Top manufacurer providing steel coil handling and packaging system per different coil size.

1. Coil handling and strapping amchine

As a manufacturer, FHOPE provides different coil packaging system per requirement.

Before offering a solution following information required.

What is the function(each station) required for the packing line, please provide the description.

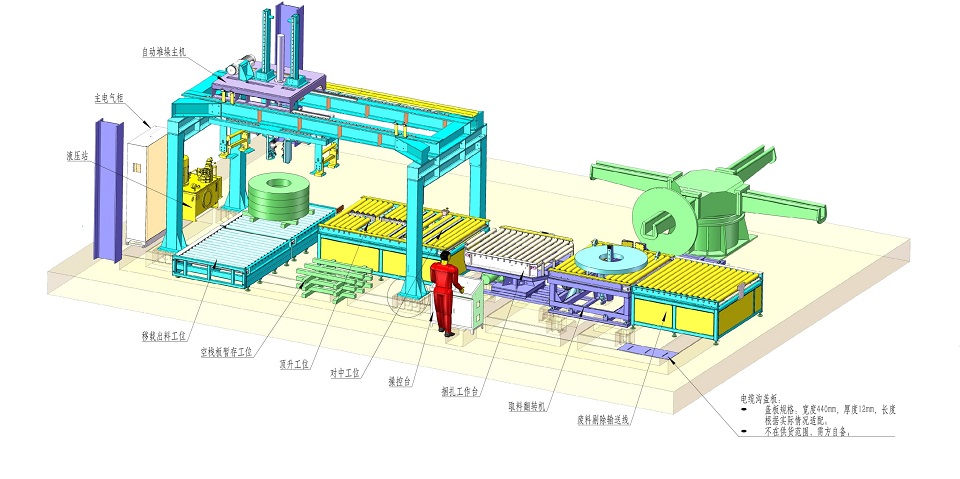

All you can choose or add the function base one following drawing.

- Basic info.

| Steel Coil No. | OD (mm) | ID(mm) | WIDTH(mm) | WEIGHT(Kg) |

| 1 | ||||

| 2 | ||||

| 3 | ||||

| 4 | ||||

| 5 | ||||

| 6 | ||||

| 7 | ||||

| … |

- Coil turnstiler: it provided by your company or us what is the Max.length of the arm?

- Strapping station:

- what is the strapping machine: manually tool Semiauto machine automatic strapping machine

- What is the strapping material: PP, PET, steel belt?

- Wrapping machine: what is the packing material, such as stretch film, paper, knit belt…?

- Stacking machine: How many stacking station required? What is the Max. stacking height?

2. Steel coil wrapping and stacking system

Operating location and resources

- LOCATION – Modernized packing line must fit to the existing packing linearea

- ONE MAN LINE – Running the modernized packing line and controlling the coil logistics between the slitting lines and packing line must be possible to handle with only one man in each

Safety

- SAFE – Safety systems must be up to date and possible to use according to safety methods.

Packing material

- COMPANY STANDARDS – Modernized line must use the packing materials according to the company standards

Equipment and automation systems

- SUPPORT – System support and spare parts available for all theequipment

- FLEXIBLE – Horizontal packing line feeding with open coil AGVstands

- PACKING CODE MANAGEMENT – Packing codes and coil information must be handled in the packing line and between the line L2 and CRM L3 automatically (coil data, AGV,)

Quality

- MECHANICAL PROTECTION – The present mechanical issues on the horizontal packages must be solved.

- MOISTURE PROTECTION – The present moisture issues on the horizontal packages must besolved

- SAFETY – The pallet strapping on the vertical line must be changed to through the eye